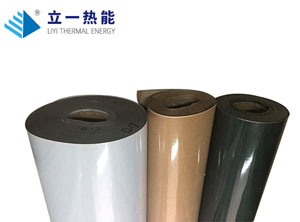

Product name: insulating paper

Product brand: a heat

Processing custom: product size limit is small, can receive for processing

Summary:

The floorboard of the insulating paper is electrical insulating paper. Is usually composed of plant fiber, mineral fiber, synthetic fiber, or their mixture by water or other medium fiber deposition on paper machine to form a thin pp material. Insulating paper has good resistance to tear strength and heat resistance performance, and small elongation, good insulation, is mainly used for the insulation of the cable, coil and other various electrical equipment materials, as well as the motor, cable, capacitor and transformer of insulation materials, laminated products, composite materials and main ingredients of presoak materials such as insulation materials.

TFT composite material, is a series of high-performance insulating paper composite products

TufQUIN110 and polyester film composite, the typical structure is a thin layer tufQUIN insulating paper, duplex polyester film, used for high temperature insulation system.

Typical applications

TufQUIN TFT composite material, typically used to 180 ° C (H) level of motor or engine, as slot insulation and slot insulation, and is also used to 200 ° C (N) in the level of dry type transformer, for layer insulation and grounding insulation.

TFT composite material, it is electric, objects, thermal equilibrium of a product, through the ascension of the insulation performance improving the working reliability of the equipment.

1.180 ° C (H) level of motor or generator, as slot insulation and meet the insulation and slot insulation

2. Dry type transformer, insulation and grounding insulation between the layers

3. The spiral coil tube

4. The line and the wiring harness around the package

5. The circuit breaker panel

6. Bus insulation

7. Capacitor insulating layer

8. Current-carrying wires and components

9. Dc coil insulation

The main features

1. High toughness

2. Excellent dielectric properties

3. High thermal conductivity

4. Easy to plug embedded

5. A certain hardness, resilience